Toe protection (SB)

Your toes are a very vulnerable part of your body, especially in a work place. Toe protection must withstand a 200 joule impact. Joule is the unit of energy and this standard is purposefully specific. Something heavy falling from a low height could have a lot less energy than something lighter from a much higher height. As well as impacts the toe area must withstand a resting mass of well over 1000kg. Most people have heard of steel toe cap boots but the protection doesn’t have to be steel. In fact there are advantages to alternatives. Non-metallic protection can be equally as strong but lighter.

Antistatic protection (A)

Clothing, seating materials, and climate factors can cause a build up a static charge of electricity in the body. Some materials in footwear can over insulate the body causing the charge to be held. When you then touch something the charge can rush from your body quickly causing a spark and a small uncomfortable shock. Antistatic footwear will significantly reduce this effect but does not offer protection for exposure to electronics and explosives work. You will need Electro-Static Protection (ESD) for this.

Midsole penetration protection (P) – SB-P, S1-P, S3, S5

Sharp objects where we walk and stand are a significant risk not only in the workplace but also outdoors and at home. Midsole protection will guard against nails and other objects. To meet this standard the footwear must be able to resist a penetration force of 1100N. Midsole protection is provided in one of these methods: a stainless steel insert in the sole, aluminium insert in the sole, or by Kevlar insole. The Aluminium and Kevlar solutions are the most flexible and lightest and cover the greatest area of the foot. Kevlar insoles also offer much higher thermal insulation.

Energy Absorption (E)

Energy Absorption of the seat region.

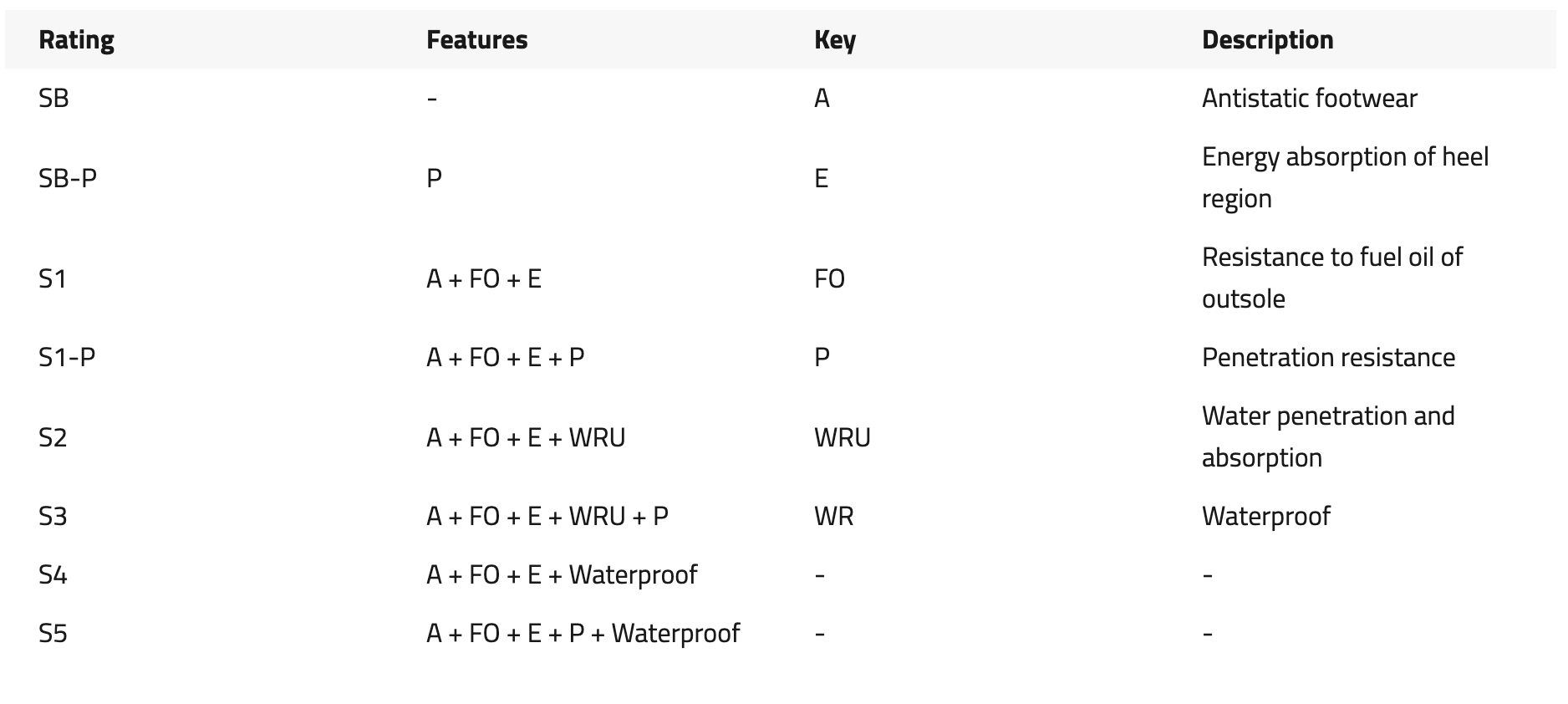

Safety Ratings Explained

SB – The rating SB indicates that the safety footwear has a 200 joule toe protection. It can have additional features but it is the most basic of safety footwear.

SB-P – has the same features as the SB rating with the addition of the midsole penetration protection. This can be a stainless steel insert in the sole, aluminium insert in the sole or by Kevlar insole.

S1 – S1 in addition to 200joule toe cap is classed as antistatic footwear. The sole is also resistant to fuel oil and has energy absorption in the heel area.

S1-P – S1-P has the same features as the S1 rating with the addition of the midsole penetration protection. This can be a stainless steel insert in the sole, aluminium insert in the sole or by Kevlar insole.

S2 – S2 in addition to 200joule toe cap, is classed as antistatic footwear. The sole is also resistant to fuel oil and has energy absorption in the heel area. It also has a water resistant upper.

S3 – S3 has the same features as the S2 rating with the addition of the midsole penetration protection. This can be a stainless steel insert in the sole, aluminium insert in the sole or by Kevlar insole.

S4 – S4 in addition to 200joule toe cap, is classed as antistatic footwear. The sole is also resistant to fuel oil and has energy absorption in the heel area. It is waterproof none as leak proof

S5 – S5 has the same features as the S4 rating with the addition of the midsole penetration protection. This can be a stainless steel insert in the sole, aluminium insert in the sole or by Kevlar insole.

Footwear which has passed the EN test for slip resistance will be marked with one of the following codes, SRA, SRB or SRC.

The codes indicate that the footwear has met the specified requirements when tested as follows

SRA – tested on ceramic tile wetted with dilute soap solution;

SRB – tested on smooth steel with glycerol;

SRC – tested under both the above conditions.